Why Choose Intact Engineering as your Zamak (white metal) Pressure Die Casting Manufacturer?

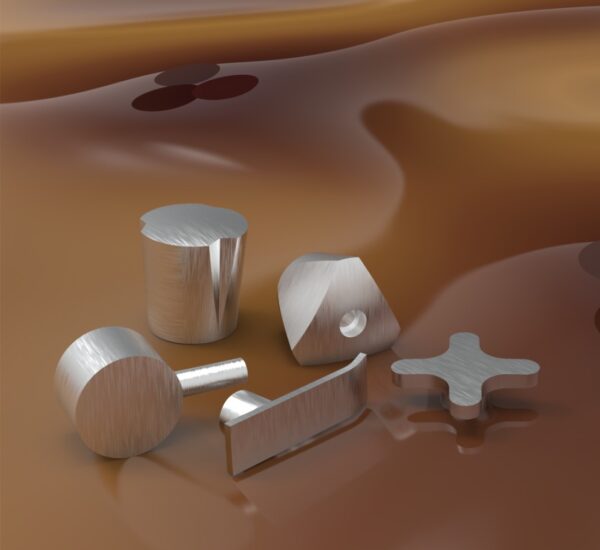

Intact Engineering is a leading zinc die casting producer with clients ranging from large appliance manufacturers to the automotive sector and beyond, from design idea to production and packaging.

Intact Engineering is a problem-solver. We can turn even the most difficult design criteria into a polished product.

From mould design and testing to zinc component manufacturing, finishing, and packing, PHB handles all phases of zinc die cast manufacturing.

ZINC ALLOY DIE CASTING IS:

High-pressure zinc alloy die casting is one of the most efficient and adaptable high-volume manufacturing methods for producing strong, precise, and complicated metal components. There are two types of zinc die castings. The typical alloys, also known as ZAMAK alloys, are called after the order in which they developed. Alloy 3, Alloy 5, and Alloy 7 are a few of them. Then there are ZA zinc alloys, which include more aluminium than typical alloys. The ZA-8, ZA-12, and ZA-27 are among them. ZA alloys are stronger and have more useful bearing characteristics.

Zink Alloy Die Casting Characteristics.

- A low-cost raw material

- Thermally conductive

- Electrically conductive

- Excellent in accuracy and stability with high dimensions

- Incredibly strong with a great hardness

- Able to cold form, which eases joining

- Exceptionally corrosion-resistant

- Fully recyclable